|

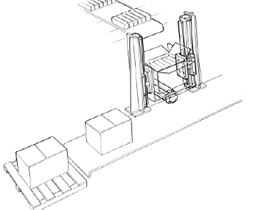

Problem #1 - Automated Baking Application

A major

U.S. food processing company

in the consumer products

market approached with a problem. Packaging of portion controlled

crackers designed

for the restaurant and food

service markets was suffering

from continued downtime. The

combination of loading, and

the required production

speeds and cycles, caused

the gradual misalignment of

the separate rodless cylinder

and linear bearing units

employed in the application. In

turn, this led to complete

system failure and a costly realignment

procedure.

Our Solution

The single unit Powerslide

from Hoerbiger-Origa replaced

the separate cylinder and

guide previously supplied by

Tol-O-Matic. Installed as an

integral actuation-guidance

system, the Powerslide is prealigned

and never goes out of

alignment, even under the

repetitive, high duty-cycle

conditions. Powerslide delivers very high

reliability levels: there has

been no downtime in the linear

motion system at the company in

the 12 month operating period

following the fitment of

Hoerbiger-Origa equipment.

As a one-piece unit,

Powerslide cuts down

engineering and installation

time and costs, and has been

easily retrofitted to the existing

machines. The single unit Powerslide

from Hoerbiger-Origa replaced

the separate cylinder and

guide previously supplied by

Tol-O-Matic. Installed as an

integral actuation-guidance

system, the Powerslide is prealigned

and never goes out of

alignment, even under the

repetitive, high duty-cycle

conditions. Powerslide delivers very high

reliability levels: there has

been no downtime in the linear

motion system at the company in

the 12 month operating period

following the fitment of

Hoerbiger-Origa equipment.

As a one-piece unit,

Powerslide cuts down

engineering and installation

time and costs, and has been

easily retrofitted to the existing

machines.

Problem #2 - Lab Filler Applciation

A manufacturer of an automated laboratory system needed to

raise a vial to a fill position where powder was to be discharged. A

vacuum operation subsequently took place, which was repeated

several times.

Our Solution

An Origa P210/20 Rodless cylinder was used with a platform

attached to the yoke; the cylinder itself is forming a major

structural member of the unit. The results were reduced engineering content, increased safety and a cost effective solution. An Origa P210/20 Rodless cylinder was used with a platform

attached to the yoke; the cylinder itself is forming a major

structural member of the unit. The results were reduced engineering content, increased safety and a cost effective solution.

More Solutions Available:

Potato Sweep

Bakery Ejector

Cheese Bagger

Fish Transfer

Please note that Simmons Industrial is capable of supplying any solution posted on our site.

|